Brochure

Download our document to see specific data of the service and how we work.

Let’s Start Work

Together

Please feel free to contact us. We will get back to you with 1-2 business days. Or just call us now.

How can we help?

We set the discipline that applies engineering, physics, engineering mathematics, and materials science principles to design, analyze, manufacture, and maintain mechanical systems. It is one of the oldest and broadest of the engineering disciplines since early times.

Technically, mechanical engineering is the application of the principles and problem-solving techniques of engineering from design to manufacturing to the marketplace for any object. Mechanical engineers analyze their work using the principles of motion, energy, and force.

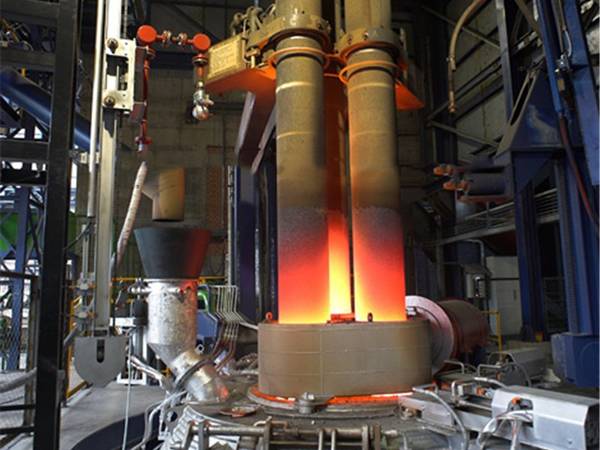

Graphite Electrodes for Steel Mills

Graphite Electrodes are essential components in electric arc furnaces (EAFs), used in the steelmaking process to generate intense heat for melting and refining scrap metal. We supply high-quality graphite electrodes specifically designed for steel mills, ensuring efficient and reliable operation.

Key Features of Our Graphite Electrodes:

- High Purity: Our electrodes are made from high-purity graphite, minimizing impurities that can affect conductivity and performance.

- Excellent Conductivity: Graphite is an excellent conductor of electricity, ensuring efficient energy transfer and optimal heat generation.

- Superior Strength: Our electrodes are designed to withstand the mechanical stresses of the EAF environment, including weight, temperature, and electrical current.

- Resistance to Oxidation: Graphite electrodes have good resistance to oxidation, ensuring long service life and minimizing electrode consumption.

- Customized Sizes and Shapes: We can supply electrodes in various sizes and shapes to meet the specific requirements of your EAF.

Benefits of Using Our Graphite Electrodes:

- Improved Energy Efficiency: Our high-quality electrodes maximize energy efficiency, reducing operating costs.

- Increased Productivity: Our electrodes contribute to faster melting and refining times, increasing production capacity.

- Reduced Electrode Consumption: Our electrodes are designed to minimize consumption, reducing operational costs and downtime.

- Enhanced Steel Quality: The use of high-quality electrodes can help improve the quality of the steel produced.

- Reliable Performance: Our electrodes are manufactured to stringent quality standards, ensuring consistent and reliable performance.

Applications in Steel Mills:

- Electric Arc Furnaces (EAFs): Our electrodes are primarily used in EAFs for melting and refining scrap metal to produce various steel grades.

- Continuous Casting: Our electrodes can also be used in continuous casting machines to provide heat for reheating the steel billet.

Types of Graphite Electrodes We Offer:

- Needle Coke-Based Electrodes: These electrodes are made from needle coke, a high-quality form of graphite, offering excellent properties for EAF applications.

- Petroleum Coke-Based Electrodes: These electrodes are made from petroleum coke, a lower-cost alternative to needle coke, suitable for certain applications.

- Ultra-High-Power Electrodes: Designed for high-power EAFs, these electrodes offer exceptional performance and durability.

By supplying high-quality graphite electrodes, we aim to contribute to the efficient and productive operation of steel mills, ensuring the production of high-quality steel products.