Copper has been one of the most trusted industrial materials for centuries. Its exceptional thermal conductivity, durability, corrosion resistance, and mechanical stability have made it indispensable across multiple sectors. Among its many applications, copper mould tubes stand out as a critical component that drives efficiency, precision, and quality across modern manufacturing.

From high-speed steel casting to glass container production to injection molding in plastics, copper mould tubes quietly but powerfully enhance output, reduce defects, and maintain strict dimensional accuracy.

This article explores how copper mould tubes support and transform three major industries: metallurgy, glassmaking, and plastics.

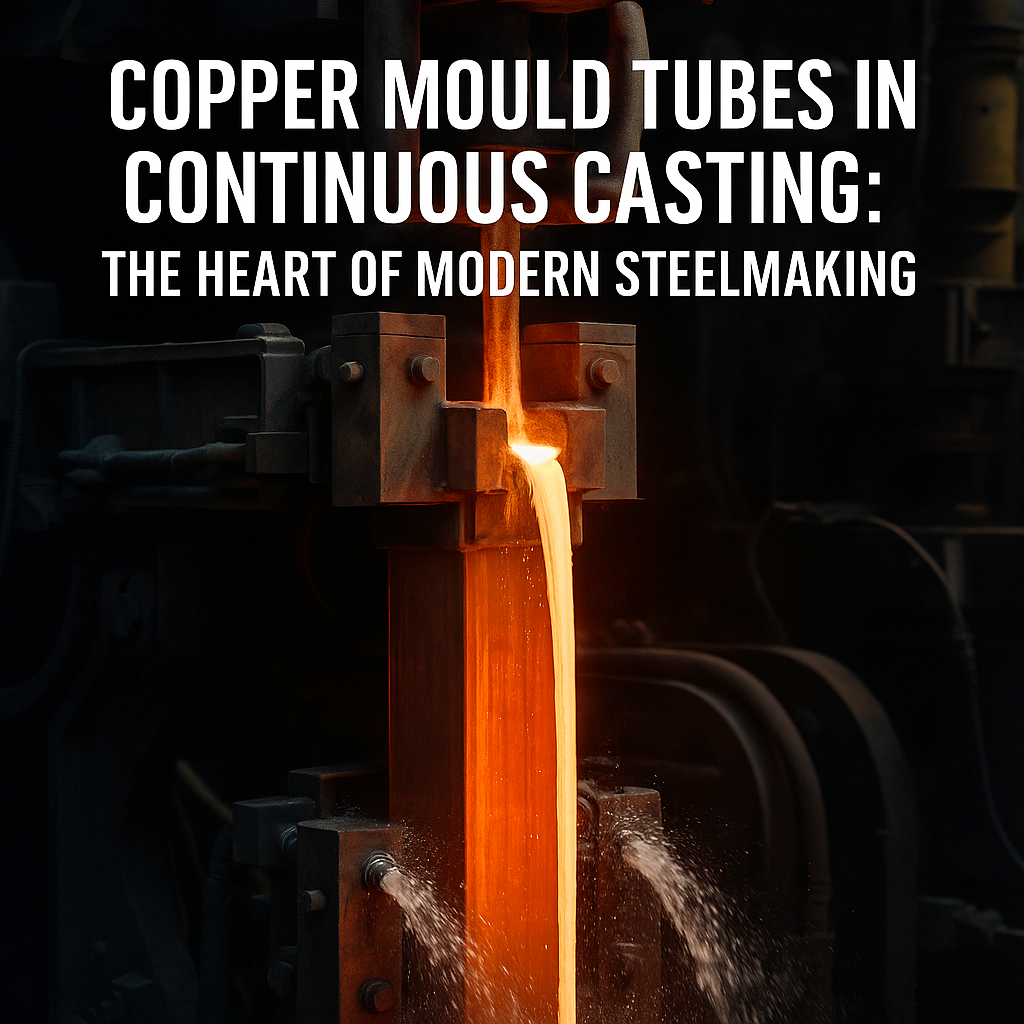

1. Copper Mould Tubes in Continuous Casting: The Heart of Modern Steelmaking

Continuous casting revolutionized the global steel industry. Instead of pouring molten steel into individual ingot molds—an inefficient and slow process—steel is now continuously fed from the ladle to the tundish and then into a water-cooled copper mould tube where the strand begins to solidify.

This is where the copper mould tube becomes indispensable.

● Rapid Heat Extraction = Faster Shell Formation

Copper is one of the best conductors of heat among industrial metals.

It extracts heat quickly and uniformly, helping the molten steel form a strong outer shell much faster. This reduces breakout risks and allows for higher casting speeds, directly increasing productivity.

● Resistance to Thermal Fatigue and Deformation

Continuous casting involves extreme temperature fluctuations and mechanical stress.

High-grade copper alloys—such as Cu-DHP, Cu-Ag, and Cu-Cr-Zr—resist:

thermal erosion

deformation

cracking

This ensures longer mold life and more stable casting performance.

● Superior Surface Quality

Because the mould is the final shaping tool before solidification, its cooling performance affects billet, bloom, and slab quality.

Effective mould cooling helps minimize:

oscillation marks

corner cracks

shrinkage defects

surface irregularities

A high-quality copper mould tube therefore enhances product quality, process speed, and operational consistency.

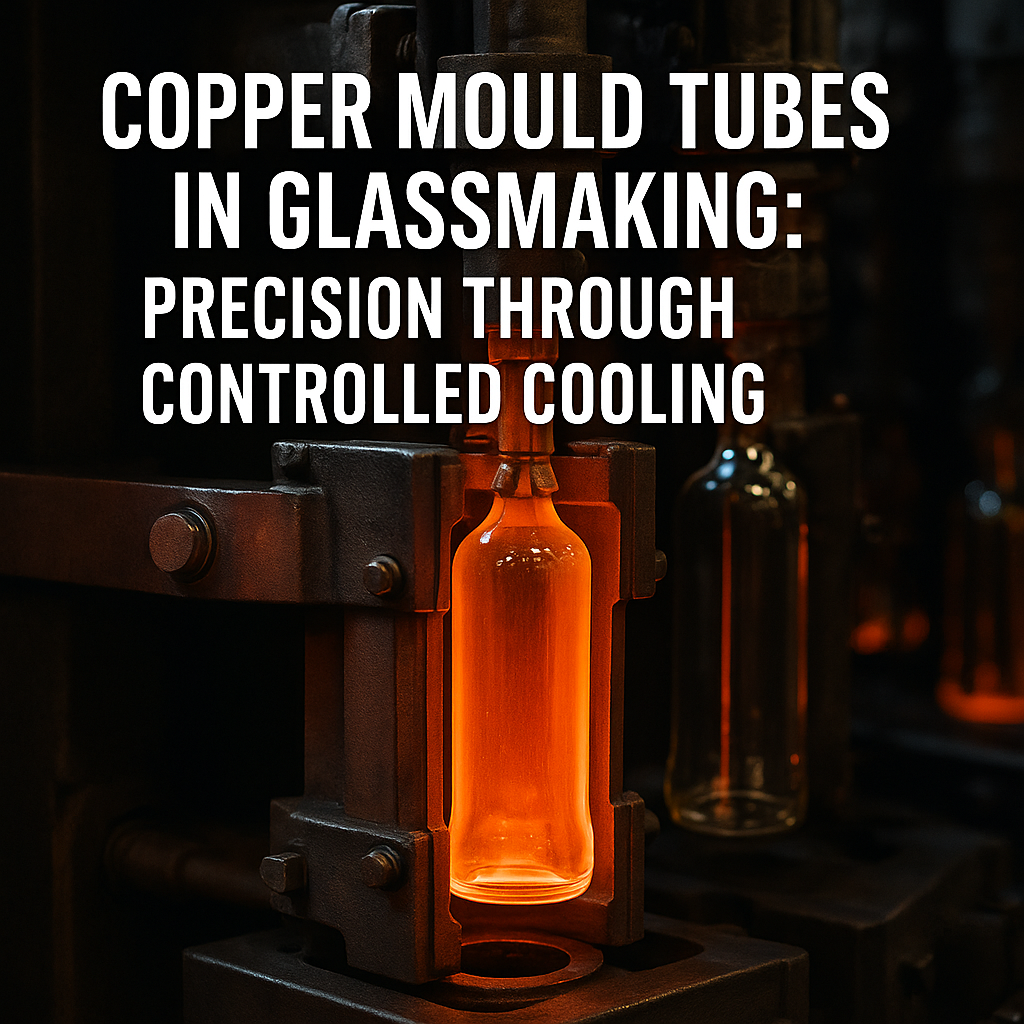

2. Copper Mould Tubes in Glassmaking: Precision Through Controlled Cooling

In the glass container industry—where bottles, jars, and specialty containers are produced—copper mould tubes ensure precise thermal management during shaping and cooling.

● High Thermal Conductivity Enables Rapid Cooling

Molten glass must be cooled quickly yet uniformly to maintain clarity and prevent distortion.

Copper mould tubes allow:

smoother surface finish

minimized deformation

tighter dimensional accuracy

reduced cycle times

For high-volume glass manufacturing, these benefits significantly enhance output and overall efficiency.

3. Copper Mould Tubes in Plastic Injection Molding: Speed and Dimensional Accuracy

In plastic injection molding, cooling time is the longest and most critical part of the cycle. Productivity depends heavily on how quickly and uniformly the molten plastic cools within the mold.

Copper mould tubes provide a major advantage by acting as efficient heat exchangers.

Benefits in Plastic Manufacturing:

Faster heat dissipation, reducing cooling time

Greater dimensional stability in molded products

Less warping and shrinkage due to uniform cooling

Higher production rate in high-volume conditions

With copper’s unmatched thermal performance, manufacturers achieve both speed and precision.

4. Why Copper Mould Tubes Remain Irreplaceable Across Industries

Regardless of the industry, one truth remains constant:

Quality production depends on precise thermal control.

Copper mould tubes deliver that control through:

exceptional thermal conductivity

rapid and uniform solidification

reduced defect rates

consistent dimensions

shorter production cycles

improved overall efficiency and profitability

Their impact makes them a core component of modern manufacturing systems.

Conclusion: The Silent Architect of Industrial Efficiency

From steel and glass to plastics, copper mould tubes work quietly but form the backbone of high-precision manufacturing. Their ability to cool rapidly, uniformly, and reliably leads directly to:

higher product quality

faster cycle times

less waste

reduced downtime

increased profitability

As industries continue to evolve with more advanced manufacturing technologies, the importance of copper mould tubes will only grow. Investing in high-quality mould tubes means investing in a more efficient, precise, and globally competitive production system.