Valves are not just accessories in an industrial pipeline—they are control points that dictate the safety, flow, and efficiency of entire processes. Whether it’s managing the flow of water in a treatment plant or regulating pressure in a refinery, choosing the right valve determines operational reliability and energy efficiency.

Did You Know? Poor valve selection or maintenance is one of the top five causes of unplanned plant shutdowns worldwide.

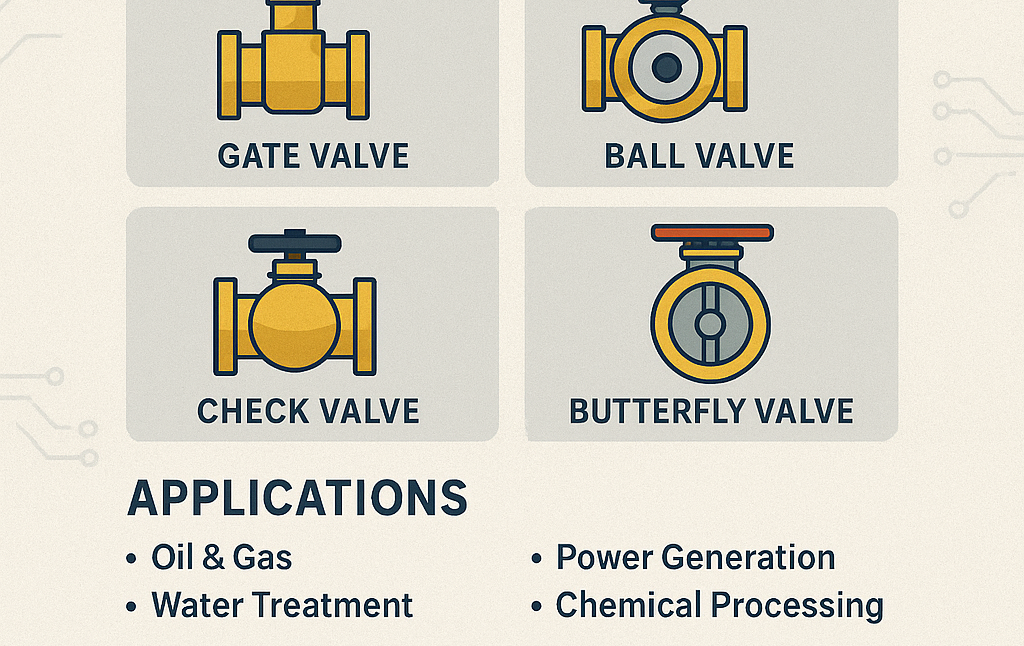

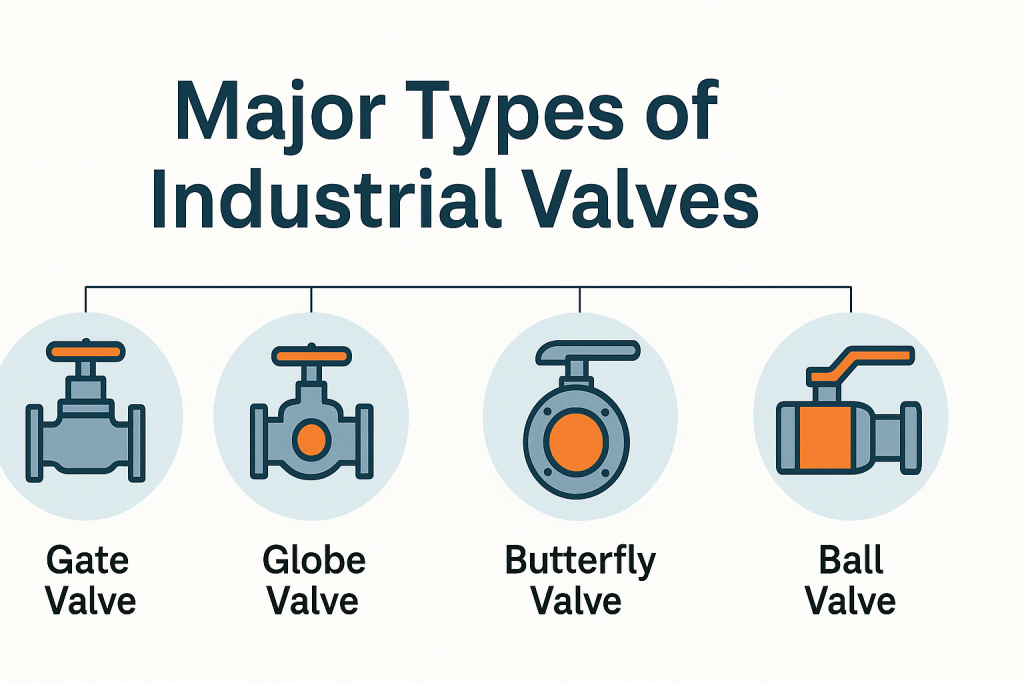

Industrial valves come in a wide range of designs, each suited to specific process requirements. Here’s an overview of the most widely used types:

Ideal for isolating or regulating flow, butterfly valves are compact and cost-effective, operating via a quarter-turn disk. Their design allows easy installation in large-diameter pipelines.

Applications: Water treatment plants, HVAC systems, chemical networks

Benefits: Lightweight, quick to operate, and space-saving

Check valves prevent reverse flow, thus protecting sensitive equipment like pumps and compressors. They operate automatically without human intervention.

Applications: Pipelines in water, chemical, and gas systems

Variants: Swing check, lift check, wafer check

These valves protect against over-pressurization by automatically venting excess pressure from vessels or pipelines.

Applications: Boilers, pressure tanks, gas storage units

Features: Precise actuation under calibrated pressure settings

Best for on/off service where a straight-line flow of fluid is desired. They offer low pressure drop and are widely used in high-pressure applications.

Applications: Waterworks, petrochemicals, marine systems

Drawback: Not ideal for throttling applications

Known for superior throttling, globe valves regulate flow with a spherical body and internal partition.

Applications: Refineries, pharma plants, thermal power stations

Advantages: Excellent shutoff capability and precise control

With industries moving towards automation and sustainability, valves too are undergoing a transformation:

IoT-Enabled Smart Valves: These gather real-time performance data and allow predictive maintenance.

Laser-Hardened Seats: Increasing erosion resistance in abrasive flows.

Nanocoated Valve Surfaces: Minimize scaling and corrosion.

AI-Assisted Diagnostics: Machine learning models are used to predict valve failure before it occurs.

🔍 Trend Focus: EU, China, and India are leading adoption of eco-friendly coatings, smart diagnostics, and low-maintenance actuator systems.

What is the medium—liquid, gas, slurry, or mixed phase?

What level of flow control accuracy is required?

What is the operational pressure and temperature range?

Will the system be automated or manually controlled?

Are there space or access limitations in the pipeline layout?

Answering these can significantly narrow down the ideal valve type.

| Valve Type | Body Material | Seat Material | Suitable For |

|---|---|---|---|

| Butterfly Valve | Ductile Iron | EPDM/NBR | Utility water, HVAC |

| Gate Valve | Cast Steel | Metal seated | Oil & gas pipelines |

| Check Valve | Stainless Steel | Metal/Polymer | Pump discharge lines |

| Pressure Valve | Forged Alloy | SS316/NACE | Steam, high-pressure gas systems |

Materials affect corrosion resistance, temperature tolerance, and pressure endurance—making them vital to system longevity.

Rather than acting as intermediaries, we position ourselves as strategic sourcing partners with technical insight and global reach. Our long-standing relationships with leading manufacturers across India, China, and the UAE allow us to deliver:

Industrial-grade valves vetted through international quality benchmarks

Guidance tailored to your specific flow, pressure, and control requirements

Documentation support for EPCs and OEMs, including pressure test certificates

Custom valve packages combining different types for complex systems

From energy conservation to plant safety, valves sit at the heart of every industrial process. Choosing wisely is a technical necessity—not a luxury. With Loyal Road Inc., you’re not just getting a valve; you’re gaining a partner committed to operational precision and long-term value.

No products in the cart.