Variable Frequency Drives (VFDs) are no longer optional — they’re essential. In today’s power-conscious, automation-driven world, VFDs allow factories to control motor speed with precision, cut down on electricity bills, extend equipment life, and reduce maintenance. Whether you’re in textiles, steel, food processing, HVAC, or water treatment — a VFD can make your operations smarter and more cost-effective.

Industry Insight: A well-installed VFD can reduce motor energy consumption by up to 60% in fan and pump applications.

A Variable Frequency Drive (VFD) is an electronic controller that adjusts the speed and torque of electric motors by varying the frequency and voltage of the power supplied.

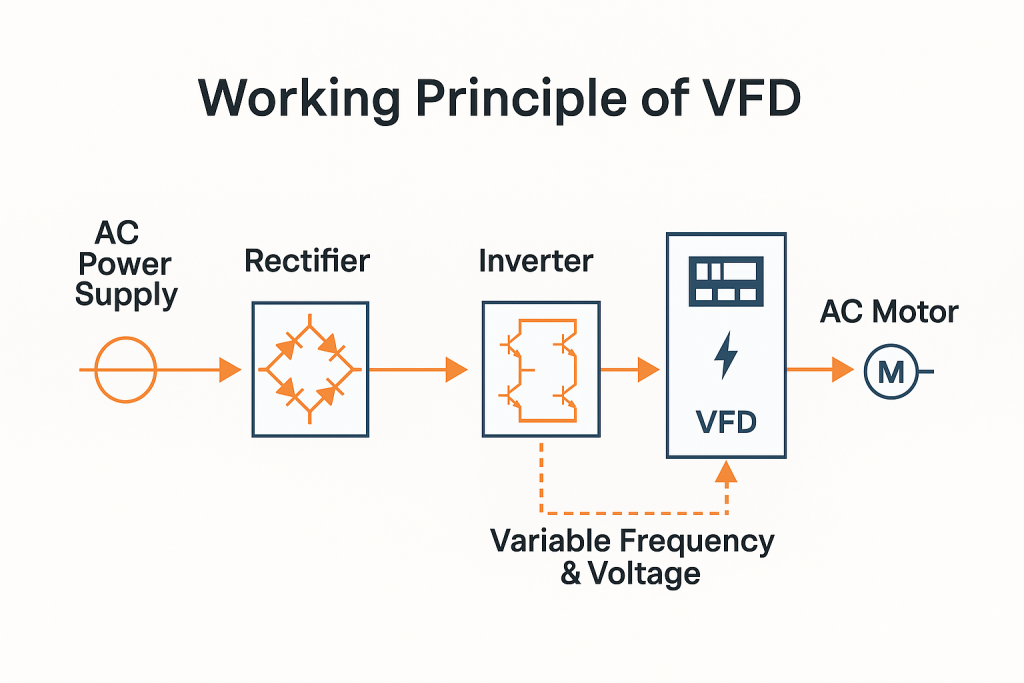

Working Principle:

Converts incoming AC power to DC

Smoothens it using capacitors

Inverts it back to variable AC with adjustable frequency

Energy Savings – Up to 30–60% in HVAC and pumping systems

Soft Start/Stop – Reduces mechanical stress on motors and connected equipment

Extended Motor Life – Less wear and tear due to controlled acceleration/deceleration

Improved Process Control – Adjust motor speed as per demand, improving efficiency

Reduced Downtime – Lower maintenance requirement means better productivity

💰 Cost Case: A medium-sized factory saved nearly $8,000/year by installing VFDs in their chilled water pumps.

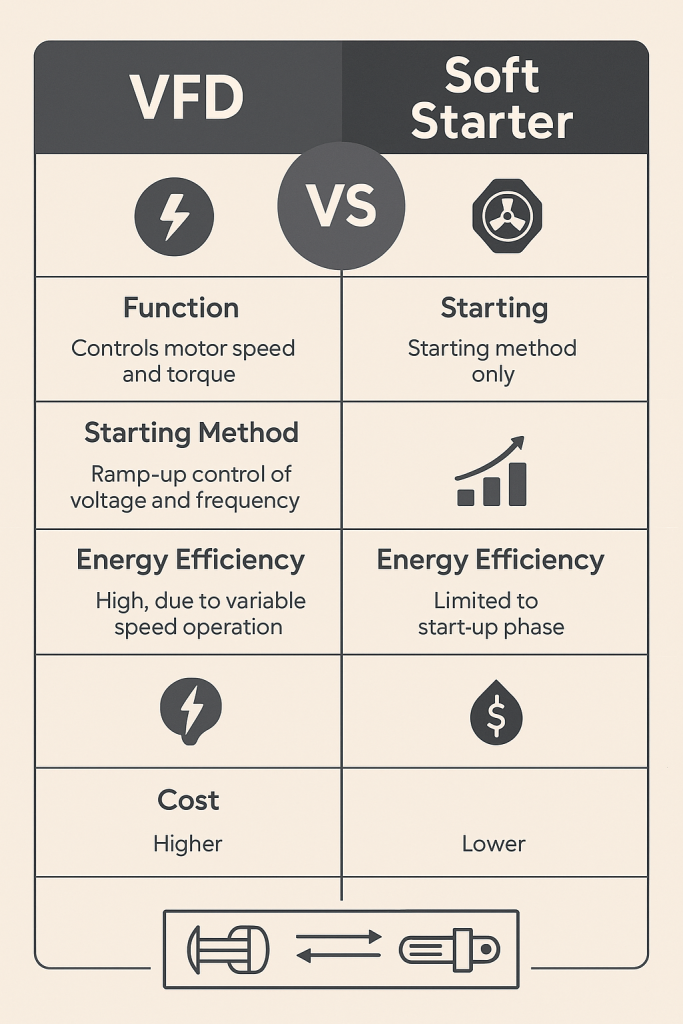

| Feature | VFD | Soft Starter |

|---|---|---|

| Controls Speed? | ✅ Yes (fully adjustable) | ❌ Only startup |

| Energy Saving | ✅ Significant | ❌ Minimal |

| Motor Protection | ✅ Excellent | ⚠️ Limited |

| Application Flexibility | ✅ Wide range | ⚠️ Narrow scope |

🌀 Fans & Blowers (HVAC, clean rooms)

💧 Pumps (water supply, chemical, sewage)

📦 Conveyors (logistics, manufacturing lines)

❄️ Chillers & Compressors (cold storage, food industry)

🔄 Mixers, Agitators (pharma, food processing)

📊 Stat Alert: Over 70% of industrial motors are used in fan and pump applications — all of which benefit from VFD integration.

What’s the motor rating (kW/HP)?

Is the load constant or variable torque?

What’s the ambient environment (dust, moisture, heat)?

Do you need braking or regeneration?

Is compatibility with existing PLC/control system ensured?

🌍 India: VFD market hit $2.5B+ driven by textile and cement

🇧🇩 Bangladesh: Growing adoption in garments, spinning mills, and ETP systems

🇨🇳 China: Smart factories using VFDs integrated with IoT & AI

🇩🇪 Germany: Energy regulations making VFD mandatory in HVAC retrofits

❌ Using wrong cable types without shielding

❌ Ignoring harmonic filtering needs

❌ Improper grounding

❌ No surge protection in control panel

🔧 Tip from the Field: Always ensure a line reactor or harmonic filter is used in long cable runs to prevent voltage spikes.

We offer:

✅ Authorized distribution of global VFD brands like Schneider, INVT, Siemens, Delta, ABB

✅ Technical selection support for industry-specific needs

✅ After-sales service & commissioning assistance

✅ Warranty-backed products with test reports and manuals

VFDs are more than just motor controllers — they’re a strategic tool for energy efficiency, process automation, and sustainability. In a competitive industrial landscape, adopting VFDs is no longer a luxury — it’s a necessity.

Partner with Loyal Road Inc. to power your progress with precision.

No products in the cart.