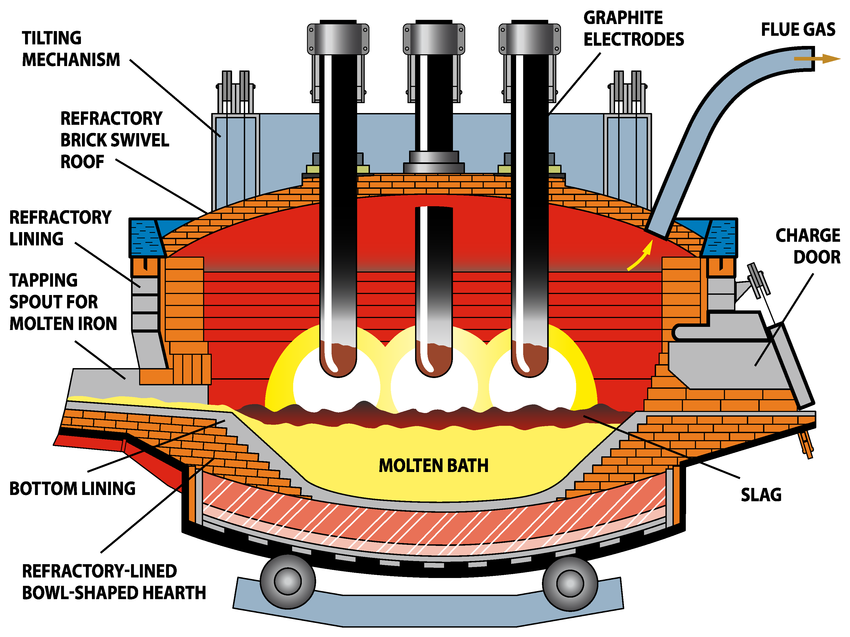

In modern steelmaking, especially in Electric Arc Furnaces (EAF), graphite electrodes are not just a consumable—they’re the core component enabling ultra-high temperature conductivity, arc stability, and energy efficiency. Choosing the right grade of graphite electrode can impact everything from furnace cycle time to final steel purity.

RP (Regular Power): Suitable for small arc furnaces

HP (High Power): For medium capacity EAFs

UHP (Ultra High Power): For large-scale, high-load operations

Each type differs in terms of allowable current density, ash content, and physical resistance.

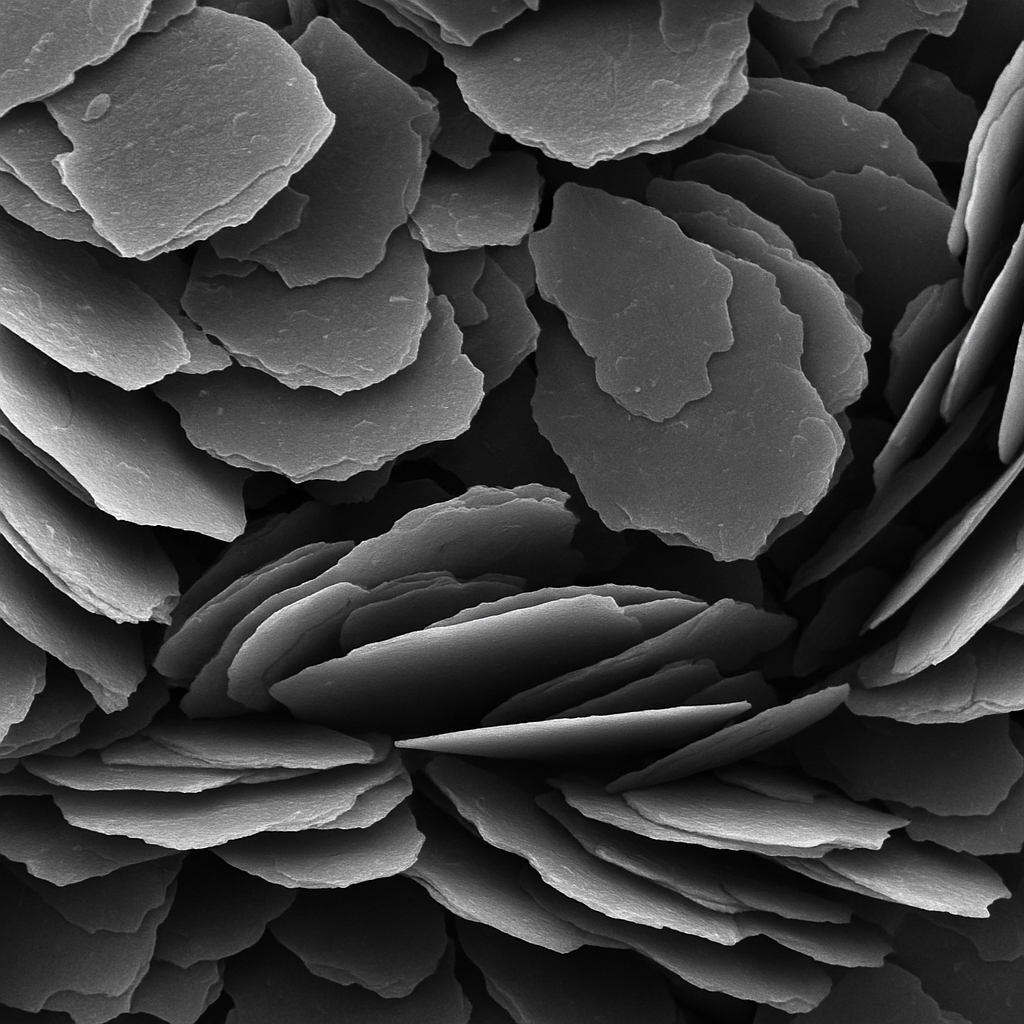

Graphite electrodes are cylindrical, high-purity carbon rods used to generate arc-based heating inside EAFs and ladle furnaces. Made primarily from needle coke, they offer excellent thermal conductivity, low electrical resistance, and structural stability at high temperatures.

Did You Know? Nippon Carbon and Showa Denko have recently implemented AI-based baking temperature control systems that reduce gas emissions by 20% during electrode production.

Graphite electrodes are indispensable in today’s energy-intensive metallurgical processes. Their role goes far beyond mere conduction—these components directly influence steel quality, furnace efficiency, and emission levels.

Key Areas of Use:

Electric Arc Furnaces (EAF):

Used for melting scrap steel at temperatures over 3,000°C. The arc between electrodes and scrap generates intense heat, making EAFs more environmentally friendly than traditional blast furnaces.

Ladle Furnaces (LF):

Vital for secondary refining—ensures desired alloy composition, desulfurization, and thermal consistency before steel casting.

Ferroalloy Manufacturing:

High-current operations like silicon manganese or ferrochrome production demand robust, ultra-high conductivity electrodes that can withstand harsh chemical environments.

Emerging Market Alert: The global graphite electrode market is expected to grow at a CAGR of 6.1% from 2024 to 2030, driven by steel recycling and green manufacturing trends.

Choosing the right graphite electrode is not just about cost—it’s about furnace lifespan, steel cleanliness, and operational uptime.

Problems Caused by Inferior Electrodes:

🔻 Premature electrode breakage during melting cycles

🔻 Arc instability causing erratic melting performance

🔻 Elevated carbon contamination in finished steel batches

🔻 Frequent replacements increase downtime and maintenance cost

Advantages of Using Premium-Grade Electrodes:

✅ High current-carrying capacity and uniform bulk density

✅ Better joint integrity with precision-fit nipples

✅ Lower ash content ensures superior steel purity

✅ Strong resistance to thermal shock, oxidation, and delamination

📊 Fact: Upgrading from HP to UHP electrodes can reduce electrode consumption by 15–25% per ton of steel, depending on furnace efficiency.

In an era where steel production is under pressure to be cleaner, faster, and more efficient, graphite electrode manufacturers are embracing radical innovations. These emerging technologies are not just add-ons—they are reshaping how electrodes are made, how they perform inside furnaces, and how much value they offer per melt.

One of the most energy-intensive stages in electrode manufacturing is the baking process. Traditional methods rely on fixed temperature curves, often resulting in inconsistencies and energy waste. But now, leading manufacturers like Tokai Carbon and Showa Denko are implementing AI-based control systems that dynamically adjust the baking temperature and cycle length in real time.

➡️ Benefit: This innovation has already shown up to 18–22% energy savings while improving bulk density uniformity across the electrode body.

Electrode degradation due to oxidation at high temperatures is a major cause of early failure. To combat this, some manufacturers have begun using precision laser surface treatment to create a micro-protective layer on the electrode exterior.

➡️ Benefit: This results in up to 30% longer electrode life in oxygen-rich environments, especially beneficial in ladle furnaces and open arc furnaces.

Standard binders (coal tar pitch) are now being replaced or blended with nanoparticle-reinforced alternatives, particularly nano-silicon and nano-alumina. These binders enhance the mechanical strength and reduce the risk of cracking during thermal cycling.

➡️ Benefit: In trials, nanoparticle binders improved arc stability, reduced electrical resistance, and shortened arc ignition time by 12% compared to conventional electrodes.

📊 Industry Watch: In 2025, a collaborative research between MIT and Nippon Carbon showed that integrating nano-silica into binder matrix enhanced thermal shock resistance by 15%, a breakthrough for UHP electrodes.

As environmental regulations tighten worldwide, especially in the EU and Japan, electrode plants are moving towards low-PAH binders, closed-loop gas treatment, and recycled needle coke to reduce the carbon footprint of electrode production.

➡️ Benefit: Not only are these methods eco-friendly, but they also improve furnace air quality and extend electrode lifespan under sustainable operations.

| Parameter | RP | HP | UHP |

|---|---|---|---|

| Bulk Density (g/cm³) | ~1.55 | ~1.65 | ≥1.70 |

| Electrical Resistivity (µΩ·m) | ≤10 | ≤8 | ≤6.5 |

| Flexural Strength (MPa) | ≥8.5 | ≥10.0 | ≥12.0 |

| Thermal Expansion (%) | ≤2.5 | ≤2.0 | ≤1.5 |

We supply graphite electrodes tailored for every capacity range—from RP to UHP. Each batch is certified and tested, ensuring consistent quality and performance in even the most demanding steelmaking operations.

No products in the cart.