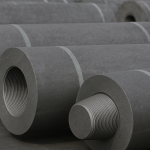

In a steel plant, even the smallest mismatch in casting equipment can cause massive inefficiencies. The copper mould tube is not just another consumable—it’s the heart of your continuous casting machine (CCM). Selecting the right tube can improve surface quality, increase production uptime, and extend equipment life.

In recent years, significant technological developments have transformed mould tube manufacturing across the globe. European manufacturers are now adopting advanced nano-coating technologies and hybrid composite plating for enhanced anti-stick properties. In India, there’s growing preference for laser-welded tubes with multi-zone taper precision, enabling mills to cast a wider range of alloys with minimal downtime. Chinese manufacturers, too, are shifting towards electron-beam welded tubes and customized cross-section design through CNC precision shaping.

Why Copper Mould Tube Quality Matters

A low-grade mould tube can cause uneven solidification, cracks in the billet, increased maintenance downtime, and rapid wear. On the other hand, a high-quality mould tube enhances thermal transfer, improves billet uniformity, and supports consistent casting cycles.

Across the globe, different regions are adopting cutting-edge technologies to optimize mould tube performance:

Europe is advancing with nano-ceramic coatings and hybrid surface plating to minimize sticking and improve billet release.

India is rapidly shifting toward multi-zone taper technology for precision heat transfer, especially in high-speed billet casters.

China is now producing electron beam-welded moulds with custom taper logic, supported by CNC precision shaping to fit unique steel grades and casting machines.

These innovations help reduce breakout rates, minimize wear, and allow for longer uninterrupted casting cycles.

Key Factors in Choosing the Right Mould Tube:

1. Material Composition

Cu-DHP: Economical, good thermal conductivity

CuCrZr: Higher strength, better wear resistance

2. Shape and Section Size

Round, Square, Rectangular — depends on billet profile

Tighter dimensional tolerance ensures better casting accuracy

3. Plating Type

Hard Chrome: Standard for good thermal transfer and durability

Nickel/Composite: Advanced resistance to sticking and erosion under high-temperature conditions

4. Inner Surface Finish

Mirror-polished surface reduces resistance during billet solidification

Reduces oxidation and improves shell integrity

5. Cooling & Taper Design

Single taper vs multi-taper: Optimized for casting speed and steel grade

Proper taper improves heat extraction, reduces shell breakage

6. Wear Resistance Parameters

Average plating thickness (≥0.20mm for chrome, ≥0.25mm for composite)

Surface hardness (≥HV900 for chrome, ≥HV1100 for composite)

Straightness deviation <0.1mm over full tube length

7. Thermal Conductivity & Fatigue Life

Cu-DHP: ~330 W/mK | CuCrZr: ~270 W/mK with better mechanical strength

Tested for ≥300 casting cycles in standard billet operation

Sourcing with Confidence

At Loyal Road Inc., we supply copper mould tubes from top-rated manufacturers in China and Europe—pre-inspected for straightness, plating quality, and dimensional tolerance. Each tube comes with a full QC certificate and is customizable to your machine’s exact needs.

Bonus Tips for Steel Mills:

Replace tubes before they reach 80% wear for best quality output

Use compatible flux and coolant to extend mould life

Consider maintaining a backup set to reduce unplanned downtime